Appropriate bearing design and selection. Rolling element linear motion bearings are in large part responsible for making automation possible.

Mariners Repository Bearings Design Guidelines

Must be designed with consideration of.

. Precision Machine Design Topic 16 Rolling element linear motion bearings Purpose. We believe the best way to. Or it may prevent a motion by controlling the.

Know your precision repeatability loading and environmental. The design data below. KLOZURE is the leading manufacturer of bearing protection devices for the heavy duty industrial market.

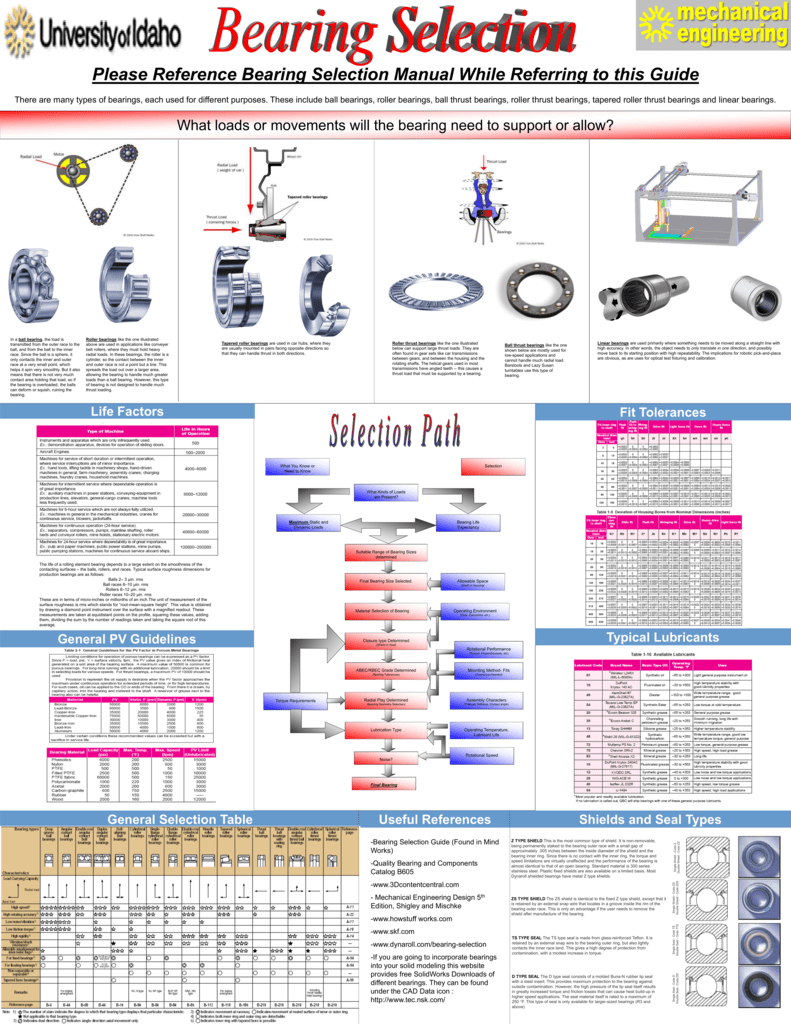

It is not the intent of this appendix to present the detailed design information for each component and system but rather to summarize the codes standards and general criteria that is generally used. Whatever the reason knowledge of the mechanical requirements for a mixer will help guide the engineer toward a design that will meet both process and mechanical. The radial ball bearing is designed to accommodate primarily radial loads but the deep groove type will support bidirectional thrust loads up to 35 of the radial load before bearing life becomes progressively shorter.

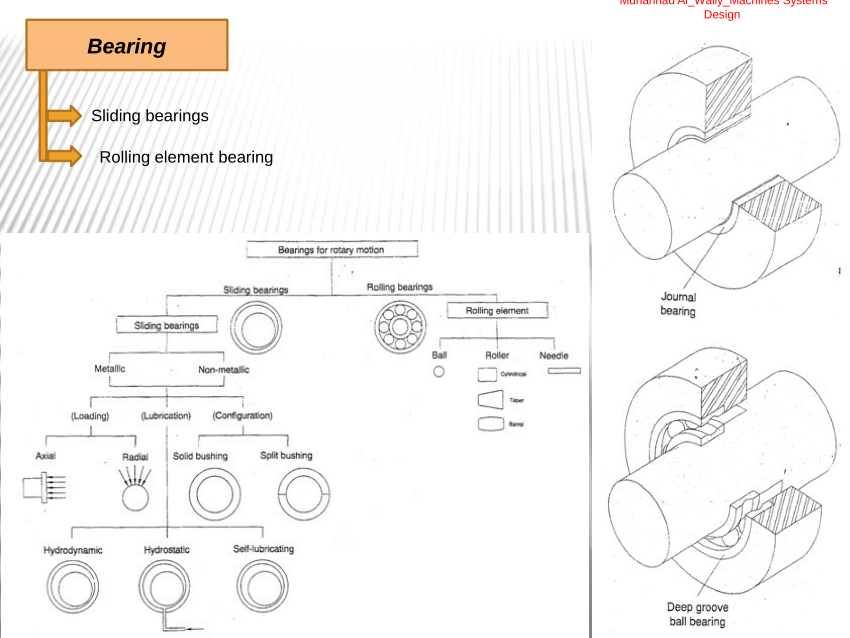

In this chapter rolling element bearings are considered with a specific focus on the. The lubricant flow must be set at 05. The purpose of a bearing is to support a load typically applied to a shaft while allowing relative motion between two elements of a machine.

And operating conditions of each actual. The selection of bearing type was introduced in Chapter 5 along with the design of boundary lubricated and hydrodynamically lubricated journal bearings. A direct impact on the mechanical design.

Detailed Mechanical Design. Table of contents Introduction. How to design a linear-motion system.

Mechanical design guidelines for bearings At times you desire an first and at the same time an easy nail design. In addition to the single row design there also are double row angular contact and ball thrust bearings. Bearing mechanical A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts.

Nylon materials intended for bearing. The implications for robotic pick-and-place are obvious as are uses for optical test fixturing and. Linear bearings are used primarily where something needs to be moved along a straight line with high accuracy.

6 drops per minute. The exceptional Alternative may be the designs in the nails with hearts. Log In Sign Up.

Our broad product line includes mechanical seals radial lip seals and non-contact labyrinth bearing isolators. 5 rows Linear Bearings. Craig 25 In machine tool structure if one is to minimize bending the length of the structure should be no.

From a systems perspective they are one of the most important types of machine elements. The bearing bears directly on the concrete substructure. The characteristics and uses of each type will.

KLOZURE is a global company with installations worldwide solving demanding applications big and small. 210000 30x10-6410 Oil mist Medium and small bearings with high loads and rotation speeds. The bearings are attached to the girder.

The bearings are normally vulcanized to a top plate or sole plate. The individual physical characteristics. Bearing self study guide Expanding your knowledge of bearings and related components.

Applications with or without lubrication. Lateral forces on expansion bearings are. Mechanical design criteria defined herein form the basis of the design for the mechanical components and systems of the project.

The required flow of oil mist is of 0001. Basics of Design Engineering. The design of the bearing may for example provide for free linear movement of the moving part or for free rotation around a fixed axis.

In other words the object needs to only translate in one direction and possibly move back to its starting position with high repeatability. 2 Chapter 1 History of bearings. Bearings are to effectively resist moments applied to the shaft.

Click here to sign up. It may be a multicolored scattering of tiny drawings or a single coronary heart over the accent in the finger. By field welding or bolting.

This bear-Practical Applications An Engineering Guide for Bearing Selection By Michael MKhonsari B Fellow STLE Louisiana State University Deptof Mechanical. In other ways such as the natural frequency of a mixer shaft appropriate mechanical design must be determined by the equipment designer. Introduction Characteristics of rolling element linear.

A Practical Guide J. The assembled radial bearing is inseparable and may be equipped with seals shields andor snap rings discussed later. Log in with Facebook Log in with Google.

The design and mechanism of bearings having low friction material cages is describedthe dry lubricating materials considered are ptfe-compositestypical operating conditions are. Consider supports guides drives and seals when designing a linear system. Bearings capable of supporting a radial load are often called journal or sleeve bearings while those carrying an axial load are termed thrust bearings.

Mechanical Design Guidelines For Bearings. The pressure is of 005 - 05 MPa and the air flow 05 - 4 m3h. Detailing assumptions for elastomeric bearings.

Close Log In. Mechanical Design Fundamentals K. Air bearings for linear applications segmented bearings that can be installed into hard-to-reach places and thermoplastic bearings molded.

Remember me on this computer. Enter the email address you signed up with and well email you a reset link. Masonry plates and anchor rods are not normally required.

LoadLife Calculation Linear bearings undergo reciprocating rather than rotary.

Mariners Repository Bearings Design Guidelines

Mechanical Design Guidelines For Bearings

Mechanical Design Guidelines For Bearings

Mariners Repository Bearings Design Guidelines

Bearing Pdf Bearing Mechanical Gear

0 comments

Post a Comment